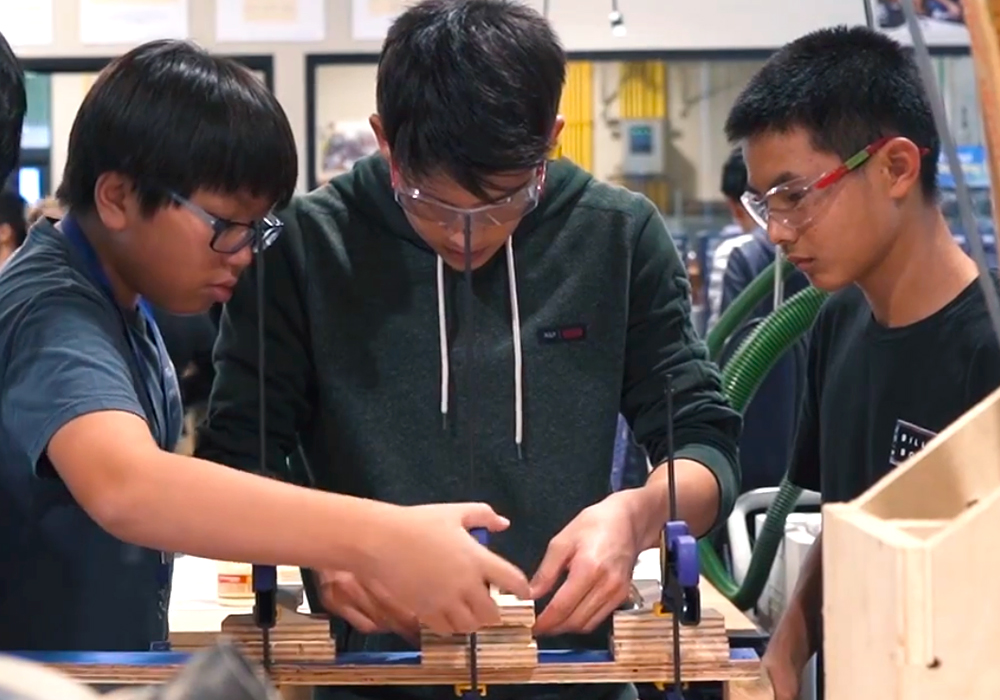

“You had a lot of failure today,” said Design Thinking, Technology and Fabrication faculty member Taryn Loveman with a smile to the students of the Rapid Prototyping and Fabrication summer school class, which took place in the newly opened D. Kenneth Richardson ’48 Learning Lab in Mamiya Science Center.

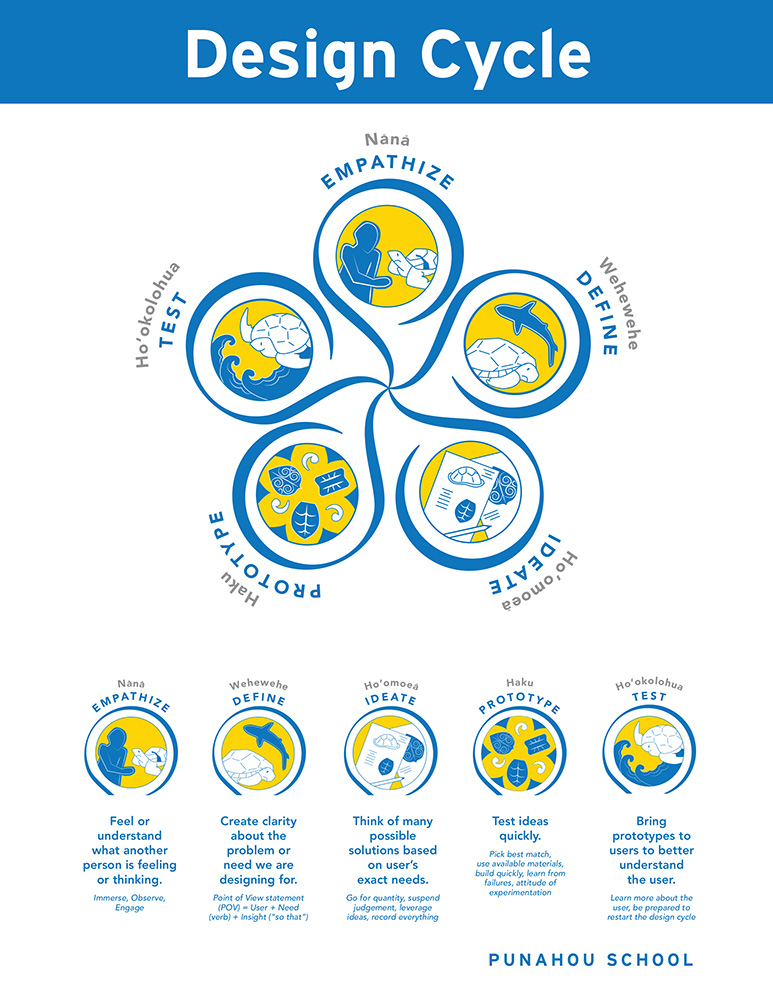

In fact, failure is an essential component of the class that’s focused on Design Thinking, which is an approach for solving problems. It is built on five basic steps – empathize, define, ideate, prototype and test.

Getting things wrong is key to the prototype and test phases of the process. How can you make something that works unless you first figure out the ways it doesn’t?

“The point of ‘failure’ is to learn about the product or client so that in the end you can make things work. The sooner we fail, the less invested we are, so it is easier to change paths and find success,” explained Loveman.

This grades 6 – 8 summer course was designed to develop students’ ability to take an idea and rapidly prototype it by making a sample using professional-level computer-aided design (CAD) software and machines, such as 3-D printers, laser cutters, a water jet, a CNC mill and CNC routers.

Here’s how they did it for a recent speedboat prototype assignment:

Empathy, Define, Ideate

Students first did research on all things boats: buoyancy, ballast and what makes boats go fast. They then brainstormed and sketched ideas before choosing an idea to prototype. Afterward, they drafted their creations using CAD software.

Prototype

Rapid prototyping machines, specifically 3-D printers, translated the designs into small plastic objects. “The printers are able to carry out the students’ very complex hull designs by extruding curves,” explained Loveman. Students then fabricated sails and supporting structures for the hulls.

Test

On race day, students put their crafts to the test in a makeshift river with the strong breeze of a fan. While some sailboats made it swiftly down the channel, others strayed to the side or capsized.

After seeing how their prototypes performed, students went back inside Richardson Learning Lab to tinker with their crafts, adding more weight here or glue there, before bringing them back out to the race area.

“We’ll see how it goes this next race, and then we can fix it if it flips over,” said one student with a mind toward iteration or trial and error. “You experienced a lot of failure today, but that’s ok! That’s the point,” Loveman celebrated.