Punahou Communications Staff

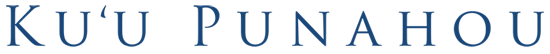

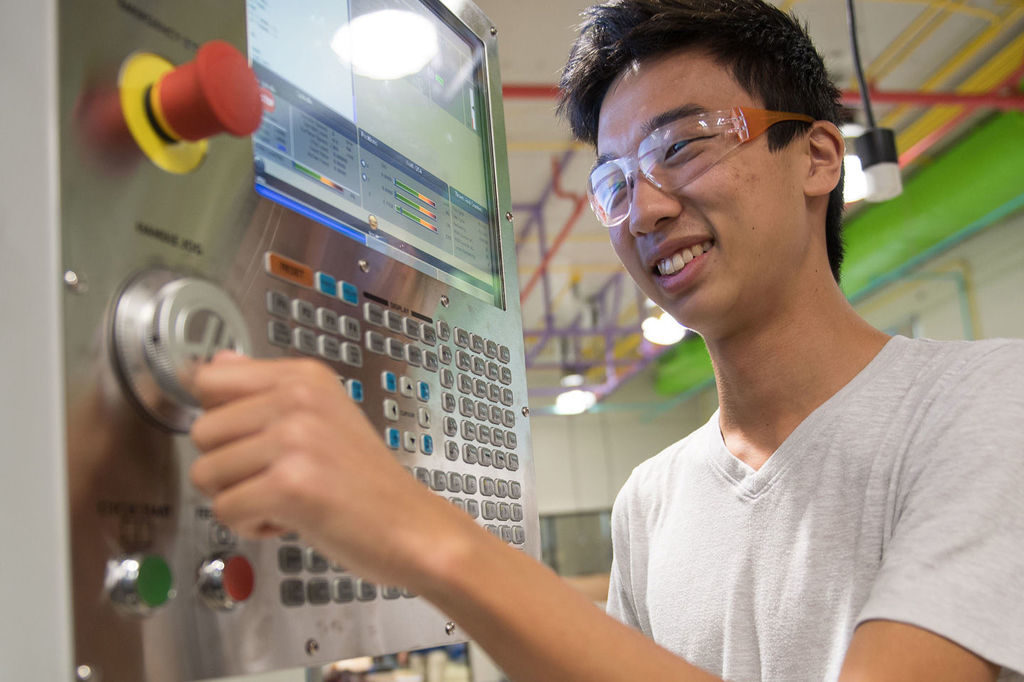

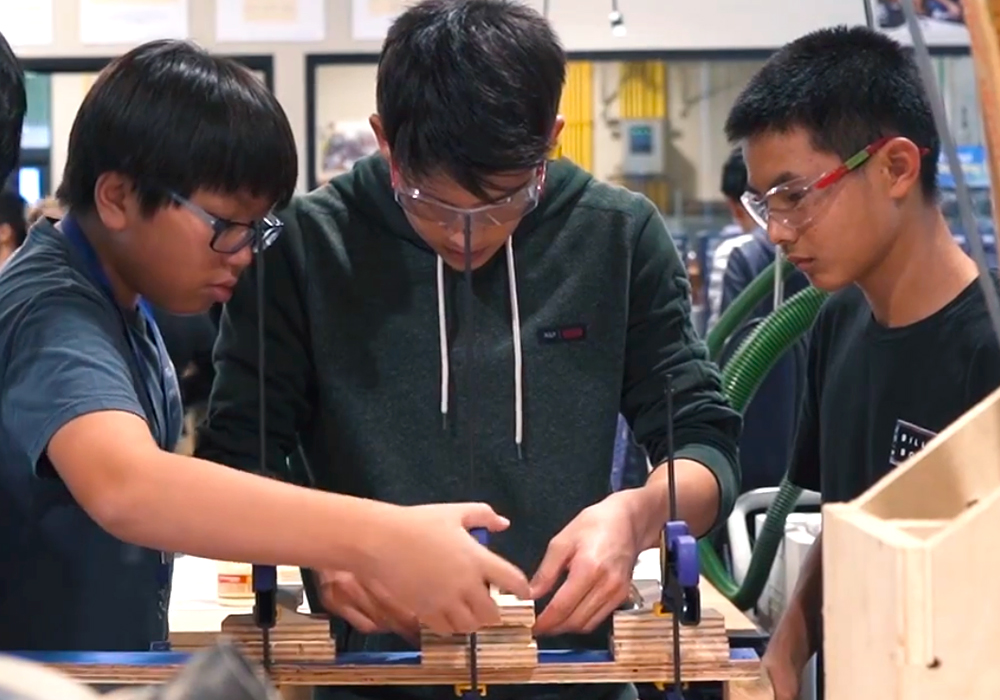

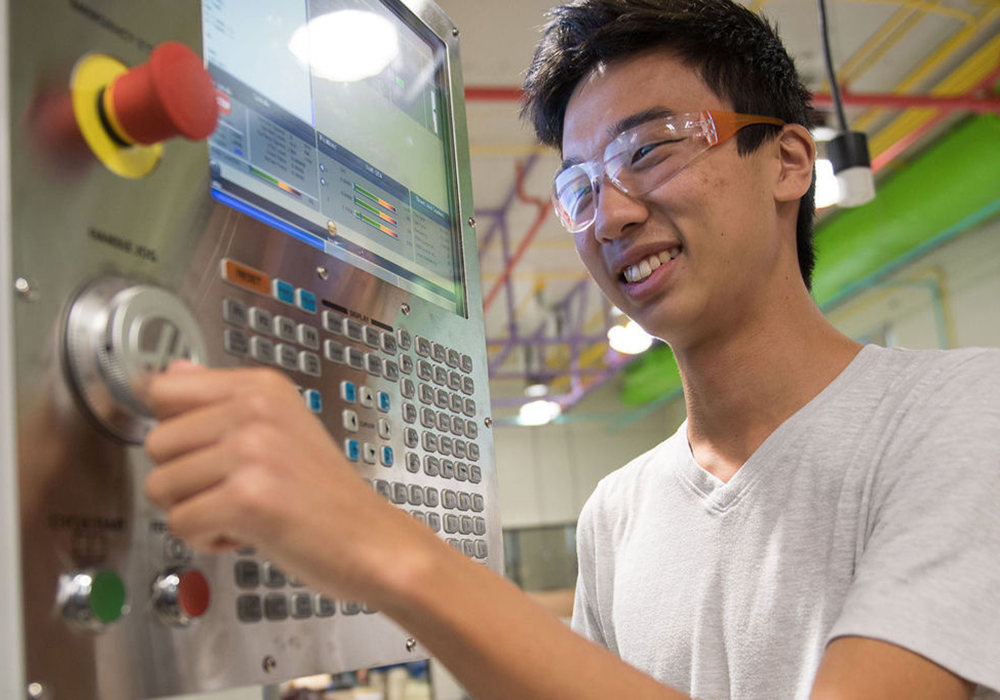

Today’s Punahou students will graduate having had access to some of the most sophisticated engineering technology available, due in large part to the D. Kenneth Richardson ’48 Learning Lab in the Mamiya Science Center. The design and fabrication makerspace supports the K – 12 Learning Commons and is a place for interdisciplinary work, where students K – 12 can design and create projects. It has the type of high-tech equipment one would find in a professional production workshop. The equipment enables students to create rapid prototypes of their designs, bringing ideas to life as part of the design thinking process.

In 2014, planning began for a redesign of the interior of the Gates Family Science Workshop to create an innovative engineering and design facility, thanks to a gift from former Hughes Aircraft president, Ken Richardson ’48. The Class of ’48 recently nominated their distinguished classmate as a Samuel Chapman Armstrong Humanitarian Awardee, which is an award given by the Punahou Alumni Association to an alumnus who has made outstanding contributions to society, garnering national or international recognition.

Over his 40-year career, Richardson rose from radar design engineer to president and chief operating officer at Hughes Aircraft Company, which at its peak employed 85,000 people. The company became the leading military electronic company in the world, developing technology that would be used by the military as well as civilians in lasers, cellphones and satellite television.

Richardson documented his tenure at Hughes in the book “Hughes After Howard: The Story of the Hughes Aircraft Company,” which was published in 2011, 10 years after Richardson’s retirement.

“His interest in inspiring leadership growth in technology advancement inspired him to give not only the D. Kenneth Richardson ’48 Learning Lab to Punahou School, but also to many scholarships throughout the country, such as at Tufts University and University of Southern California,” wrote the Punahou Alumni Association committee. “His desire is to motivate and inspire young minds to explore, implement and create.”

In the lab, students will be able to cut through heavy metal and plastic materials with water jet and laser cutters, reshape wood with computer numeric controlled machines and build objects using 3-D printers. All these tools will give students the chance to “amplify the complexity of their projects and their thinking,” says engineering faculty Justin Lai.

The D. Kenneth Richardson ’48 Learning Lab gives students a space to “realize and iterate on an idea,” said engineering faculty Aaron Dengler, “making it more precise and refined – just as they would with an English essay – creating drafts and applying what they learn to future products.”